To weaver Felicity Irons, the bulrush that sprouts in abundance along our riverbanks is reminiscent of a root vegetable. “When I’m in the workshop, I love recognising where the rushes were cut and thinking about how this raw plant - which looks like onions when it’s growing in the river - can be turned into such a range of things,” explains the Bedfordshire-based maker, whose commissions span floor matting for the Game of Thrones and Hever Castle, bedheads for the Heckfield Place hotel, basketry, tableware and even shoes.

Current projects include installations for TOAST shop windows inspired by the Spring Summer 2024 collection, Outdoor Pursuits. “I’ve come up with different weaves and tactile textures: figure eight knots tied into two-ply ropes to represent sailing, woven fish of various sizes, sun-like shapes, and plaiting that cascades down from the ceiling so you have a feeling of water,” she says of her displays, which launch to coincide with an installation for London Craft Week inside the TOAST London Notting Hill shop reminiscent of woodland dens. Constructed from rush cordage and hazel plaited with herbs and flowers, the installation will house a floor strewn with pieces of rush, meadow grasses and dried orange peel.

One of the few remaining rush weavers in the UK, Felicity taught herself the age-old craft while convalescing at home after a car accident in the early 1990s. With a loan from The Prince’s Trust, she set up a rush seating repair business (alongside selling antiques), before branching out to make new pieces from scratch. Then, in 1994, when her supplier in Cambridgeshire died, she learnt to harvest the rushes herself. “I had a lesson in punting and cutting,” she recalls. Harvesting usually begins in mid-June and lasts four to six weeks, during which time she and a small team punt along the River Ouse or River Nene, aiming to cut two tonnes of rushes each day by hand, using scythe blades mounted on ash poles (last year they cut almost 2500 bundles, or ‘bolts’ in total).

“I love harvest because I’m on my own in my punt on the river. When it’s good weather and you’re cutting really well, you can’t beat it. It’s very physical so at the end of the day you feel absolutely knackered but also really good because you’ve achieved something,” she elaborates. “We cut in different places on the river each year to allow the area to recover. There are no rushes in sight yet but once they start growing, if we have further rain, it can beat them over. That means they are harder to cut and you don’t get the quality.” Fatter rushes grow on the outside of the bed and are plaited to make items such as log baskets; finer rushes which are closer to the bank are better for woven table mats, for instance.

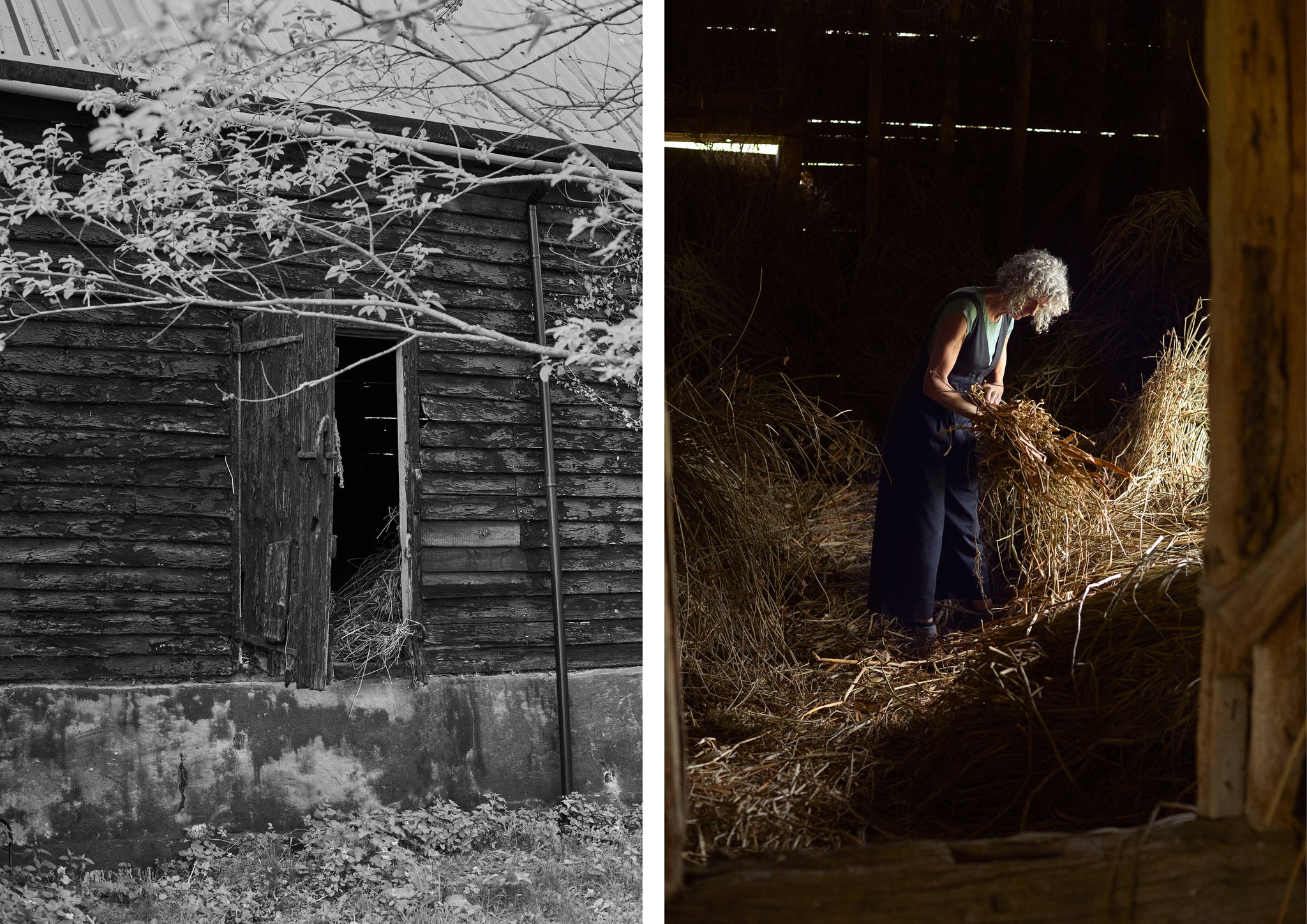

The rushes are lined up in A-shape bolts along a 500m hedge and turned daily to ensure they are fully dry before being stored in a fourteenth-century tythe barn on a working farm (she also has a two-room studio onsite; one room for sewing the floor matting and making log baskets; the other for smaller pieces). “The rushes must be soft and malleable to work with so when we select a bolt, we wet it and then use it straight away. They start out green and then mellow depending on how much they’re in the daylight; they constantly change and evolve throughout their life which I think is lovely,” continues Felicity, who employs five craftsmen full-time in the workshops, plus another half dozen who work parttime from home. “I never want the business to grow very big because then I wouldn’t get my hands dirty.”

The rushes are lined up in A-shape bolts along a 500m hedge and turned daily to ensure they are fully dry before being stored in a fourteenth-century tythe barn on a working farm (she also has a two-room studio onsite; one room for sewing the floor matting and making log baskets; the other for smaller pieces). “The rushes must be soft and malleable to work with so when we select a bolt, we wet it and then use it straight away. They start out green and then mellow depending on how much they’re in the daylight; they constantly change and evolve throughout their life which I think is lovely,” continues Felicity, who employs five craftsmen full-time in the workshops, plus another half dozen who work parttime from home. “I never want the business to grow very big because then I wouldn’t get my hands dirty.”

A truly ancient form of making (“remnants were found in Egyptian times,” says Felicity), rush weaving is on the Heritage Craft Association’s endangered red list. “I think things are changing and the association is doing its best to really push that,” she says. It helps that there are plenty of designers who believe in the beauty of rush and are keen to collaborate. “They come to me and say, this is what we’d like to do, is it possible. I thrive in that atmosphere,” says Felicity citing several past partnerships as examples. “I loved working with Faye Toogood, making plinths and woven benches for the Mulberry flagship store a few years ago. I also made armour for last year’s Warner Brothers superhero film The Flash. That was very traditional in the sense that it was based on images from an island in Indonesia where they use plant material for armour.”

Felicity also runs three rush workshops a year, teaching techniques such as plaiting, coiling and weaving (they are always fully booked). “Not everyone makes the same thing: it can be a hat, a bathmat, a wall hanging. I love passing on knowledge and my passion for rush; I find teaching very inspiring,” she says, revealing that there’s a six-to-eight-month lead time for flooring and roughly nine weeks for other pieces. “It’s a slow process, very time-consuming. I think it’s important to remember how things are made and how we use our hands. Not everything is fast or immediate. If we lose these skills, we lose something essential to ourselves.”

Visit a TOAST shop to view Felicity’s window displays, and join us at our London Notting Hill shop from Monday 13 – Sunday 19 May to see our Rush Matters London Craft Week installation.

Felicity wears the TOAST V-Neck Cotton Linen Twill Jumpsuit.

Words by Emma Love.

Photography by Ellie Smith.

Add a comment